We are Manufacturer, Supplier, Exporter of Telescopic Covers, Flattened Roof Shape Telescopic Covers, Y axis Telescopic Covers, Flat Shape Telescopic Covers, Cross Beam Telescopic Covers, Blind Telescopic Covers. We are Repairer and provide AMC (Annual Maintenance Contract) Services, Repairing Work / Services for our products and our setup is situated in Pune, Maharashtra, India.

Telescopic covers are generally produced from cold-rolled uncoated thin plates in thicknesses from 1 to 3 mm.

Units are available for short and long term rentals as well.

Wherever guideways on machines have to be protected, we have a suitable solution. Our guideway protections systems boast a high degree of operational reliability, a long service life, and make use of innovative technical solutions in vertical & cross rail application.

GUJAR ENGIFAB INDIA PVT. LTD. Telescopic covers are sturdy, most durable & designed with easily replaceable highly anti wear polyurethane & synthetic rubber wipers, dampers, phospher bronze / engineering plastic guide shoes

Wiper Systems In Various Designs For Fast-running Telescopic Covers

Rollers / Sliders

Lifting Elements

Locking Systems

Synchronising Device ( Harnesses )

AMC of Protection Covers for keeping your machines always in good healthy running condition

In this day of just in time inventories and production unplanned machine failure and its downtime due to the failure of way covers can cause major losses from idle laborers, overtime, missed deadlines and promise dates and lost of sales and profit.

We offer periodic scheduled preventive maintenance Programme for your protection covers like telescopic covers, rollway covers, and apron covers. Bellow covers, may wipers, cable drag chains etc.

Our experienced technician will visit to your works as per schedule. During his visit he will open the cover, clean and lubricate the guide ways and cover he will inspect and replace perishable items like wipers, Guide shoes, rollers, and spring etc refit the cover on your equipment.

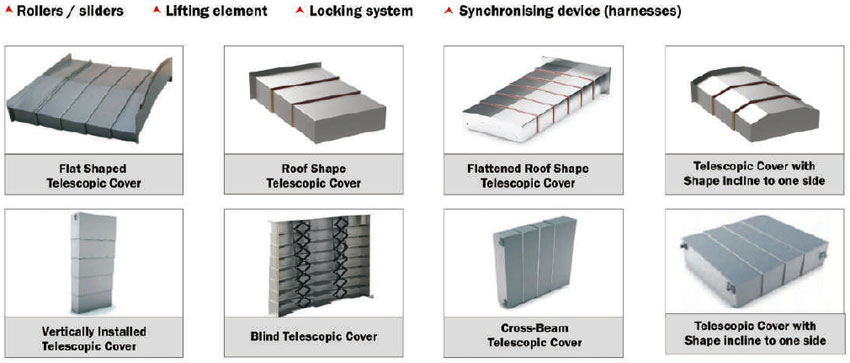

DESIGNS

Machine tools come in a wide variety of designs. That is why a modern lathe needs another type of telescopic cover than, for example, a large bed-type milling machine.The following designs provide an overview of typical designs.

- Flat Shape Telescopic Covers

The U-shaped design is generally used in a horizontal, lying position for milling table guides. With this design the maximum width of the telescopic cover should be limited to 1.5 m.

- Roof Shape Telescopic Covers

This design is always advisable when cooling lubricants are used. The inclined surface allows the water - and naturally also the chips - to run off more easily. With large covers (> 3 m width) for reasons of stability, etc. at least three roof angles should be provided. roof shape telescopic cover

- Flattened Roof Shape Telescopic Covers

The flattened roof shape is a special construction method with two roof angles. Primarily for dry operation and widths > 3 m.

- Telescopic Cover with Shape Incline to one side

The shape with incline to one side has a special roof shape. Depending on the possible incline, covers can be constructed with widths of up to 1.5 m. This shape is likewise a recommended solution when large amounts of coolant are present. Depending on the angle of incline, this form also helps to discharge coolants / chips.

- Vertically Installed Telescopic Covers

Standing covers are used on larger machine tools, mostly in the area above and below the cross beam. They can take many different shapes.

- Vertically Installed Telescopic Covers

With blind telescopic covers, the cover plates move in separate guide rails, each of which is mounted on the machine at the sides. It is used exclusively in a vertical arrangement. The guide rails are generally made of brass.

- Blind Telescopic Covers

- Cross-Beam Telescopic Covers

These covers are predominantly used on large gantry machine tools on a cross beam to the left and right of the support. The boxes are suspended vertically and protect the support guides from chips and cooling lubricants.

- Tubular cover, polygonal covers

Tubular covers or covering shafts, spindles, etc. They can be made either with a round or a polygonal shape.

- Dual-Axis Motion

Dual-Axis covers are typically moving behind the tables and under the spindle when space is limited. This design is limited to 3 boxes unless guide rails are used, and must be flat design for this style of cover.

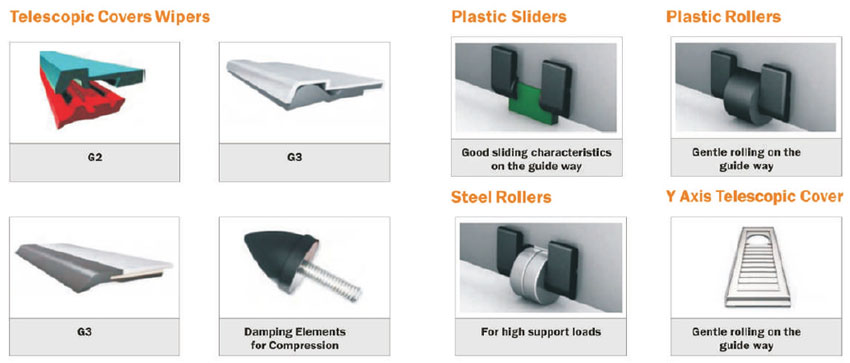

- Damping Elements for Compression

Damping elements that only work during expansion requirean additional element for compression. Here simple rubberbuffers mounted at an appropriate point on the rear wallhave proven themselves over many years

- Damping Elements for Compression - G2

G2 designed for minimal coverextension / compression lengths Replaceable wiper lips Minimal horizontal space required Minimal horizontal space required Also available with a rubber profile vulcanized on the profiled support (shown), for optimum damping properties at high traverse speeds

- Damping Elements for Compression - G3

A specially-milled steel plate profile is spot-welded to the boxes and a PUR wiper lip is inserted. Necessary calculated distance of the cover plates 3.5 to 5.5 mm.

- Damping Elements for Compressio

- Damping Elements for Compression - G4

These wipers consist of an NBR profile vulcanized onto a steel strip. Necessary calculated distance of the cover plates 2.5 to 3.5 mm.

- Plastic Rollers - Gentle rolling on the guideway

For low travel speeds

- Steel Rollers - For high support loads

For high travel speeds

- Plastic Sliders - Good sliding characteristics on the gateway

For high travel speeds. Can also be used for linear guides.

- Y Axis Telescopic Covers

Gentle rolling on the guideway